EXCLUSIVE TECHNOLOGY: ULTRA FLAT EDGELIT LED FRONT AND BACKLIGHTS

Innovation in Lighting

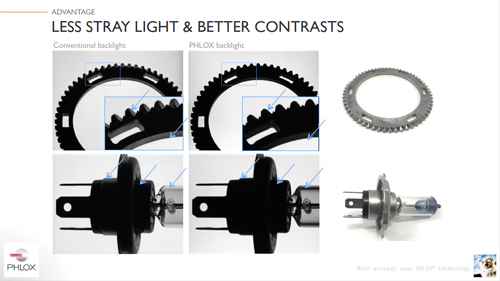

PHLOX® DOUBLE LIGHT INJECTION TECHNIQUE

PHLOX® DOUBLE LIGHT INJECTION TECHNIQUEPHLOX® uses optical processes:

a PMMA pipe lighted by a linear source made up of

LED (Light Emitting Diodes).

Our manufacturing process (CO2 laser) enables us to

combine refraction and diffusion which improves

backlight luminance. Up to 90% of the light injected

can be reemitted on the surface. Thanks to the

use of mathematical models, PHLOX® emits light in a

determinist and perfectly controlled manner.

Technological Advance

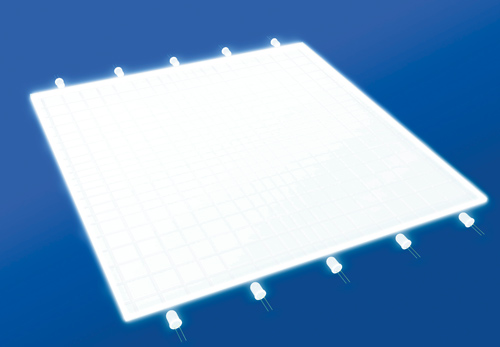

PHLOX® QUADRUPLE LIGHT INJECTION TECHNIQUE

PHLOX® QUADRUPLE LIGHT INJECTION TECHNIQUEAfter several years of research in optics and electronics

PHLOX® filed several international patents. Our

know-how is expressed in the manufacturing of

light guides according to the patented PHLOX®

process and in the optimisation of its coupling with

the light source, combined with high-grade optical

components.

The luminance of PHLOX® optical pipes can be up to twice as high as the ones using diffusion.

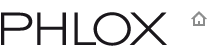

Are Phlox® Backlights really superior to competitive systems?

Let's compare.

Phlox® SLLUB Backlight 50x50mm

Other 50x50mm backlight (made in Japan)

Whatever the field of application for our technology, PHLOX® provides much more than lighting:

Better uniformity : the precision of the mathematical model and the micro prisms (< 30 µ) enable us to reach up to +/- 5 % uniformity for the backlight surface.

Higher luminance : up to 80% of the light injected is reemitted on the surface, up to twice as much as light pipes using diffusion.

More compact design : our technology is well suited to the manufacture of very thin pipes (1 mm). This feature enables us to create extra flat products in response to the need to reduce bulk for various applications.

Long life cycle : the combination of our technology and the quality of our designs ensures constant control of temperature and provides our products with an exceptional life cycle.

And a faster response : 48 hours at the most for delivery of a standard product and 5 weeks on the average for the design and delivery of a prototype or custom made product.